Are you tired of rummaging through cluttered drawers and shelves in search of your workshop tools? Do you struggle to keep your workshop organized and efficient? If so, you’re not alone. Proper tool storage is essential for any workshop, helping you save time, improve productivity, and maintain a safe working environment. In this blog post, we will delve into the world of workshop tool storage and explore the top tips and strategies to keep your tools organized, easily accessible, and well-maintained. From toolboxes and wall storage to organizing techniques and safety tips, we’ve got you covered. Get ready to transform your workshop into a well-oiled machine with our Workshop Tool 101 guide!

Different Types of Workshop Tool Storage

When it comes to workshop tool storage, there are various options available to suit different needs and preferences. Let’s explore the different types of workshop tool storage solutions:

1. Toolboxes and Chests:

Toolboxes and chests are classic storage solutions for workshop tools. They come in various sizes and designs, ranging from portable handheld toolboxes to large, stationary chests. These provide a compact and secure storage option, allowing you to store your tools in a single container and easily transport them when needed. Toolboxes and chests often have multiple compartments and drawers, enabling you to organize your tools based on size, type, or frequency of use.

2. Wall Storage:

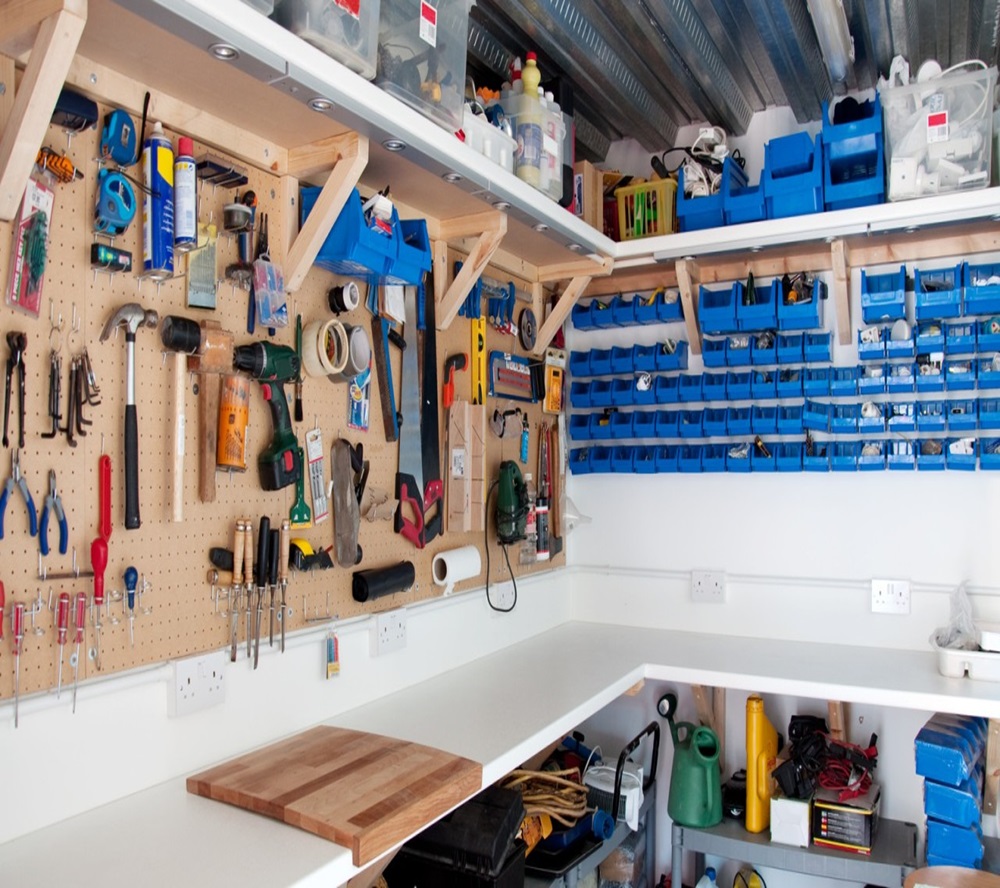

Wall storage systems are an excellent choice for maximizing vertical space in your workshop. They typically consist of wall-mounted racks, pegboards, or shelves that allow you to hang or store your tools within easy reach. Wall storage is versatile and customizable, allowing you to arrange your tools according to your specific needs. It also helps declutter your workspace and provides a visually appealing display for your tools.

3. Mobile Tool Carts:

Mobile tool carts are a practical option for those who require mobility in their workshop. These carts are equipped with wheels, allowing you to easily move your tools around the workshop as needed. Mobile tool carts often feature multiple tiers or drawers, providing ample storage space. They are particularly useful for larger or heavier tools that may be difficult to carry individually.

4. Workbenches with Storage:

Workbenches with built-in storage are an efficient way to combine workspace and tool storage. These workbenches typically feature drawers, shelves, or cabinets integrated into the design. They provide a dedicated area for working on projects while keeping your tools neatly organized and easily accessible. Workbenches with storage are available in various sizes and configurations to accommodate different workshop setups and tool collections.

5. Specialized Tool Holders:

Specialized tool holders are designed to cater to specific tools or tool categories. Examples include tool racks for wrenches, magnetic strips for holding metal tools, or foam inserts for organizing sockets. These holders offer a tailored solution for storing particular tools, ensuring they are secure and easily identifiable. By using specialized tool holders, you can optimize your storage space and keep your tools well-organized.

By understanding the different types of workshop tool storage options available, you can choose the ones that best suit your needs and create an organized and efficient workspace. In the next section, we will dive into the strategies and techniques for organizing your workshop tools effectively.

Related Article: New vs. Old Workshop Tools: New Innovation, Features, and Designs

Organizing Your Workshop Tools Efficiently

Organizing your workshop tools efficiently is key to improving productivity and maintaining a well-structured workspace. Here are some strategies and tips to help you organize your tools effectively:

1. Grouping Similar Tools Together:

Start by categorizing your tools based on their type, function, or frequency of use. This will make it easier to locate specific tools when you need them. For example, group all your screwdrivers together, separate your power tools from hand tools, or create a designated area for measuring tools. By organizing your tools into logical groups, you can streamline your workflow and reduce the time spent searching for the right tool.

2. Maximizing the Use of Vertical Space:

Utilize wall space by installing pegboards, racks, or shelves to hang or store your tools vertically. This not only saves valuable floor and workbench space but also keeps your tools within easy reach. Consider using hooks, brackets, or magnetic strips to securely hang your tools. Additionally, labeling each designated spot will ensure that tools are returned to their proper place after use, maintaining the organization.

3. Prioritizing Frequently Used Tools:

Keep tools that you frequently use within arm’s reach or in easily accessible storage areas. This will save you time and effort when grabbing the tools you use most often. Place them in tool chests or drawers close to your workstation or on a dedicated tool cart for quick access. By prioritizing your frequently used tools, you can streamline your workflow and increase efficiency.

4. Labeling Your Tools and Storage Spaces:

Labeling your tools and storage spaces is essential for maintaining organization and ensuring that tools are returned to their designated spots. Use durable and clear labels to identify the contents of drawers, cabinets, or toolboxes. You can also label individual tools with their names or use color-coding systems for easy identification. Clear labeling eliminates confusion and helps others in the workshop find and return tools to their proper place.

By implementing these organizing strategies, you can create a well-structured and efficient workspace. In the next section, we will discuss the importance of maintaining your workshop tool storage and how to keep your tools in optimal condition.

Related Article: The Ultimate Guide to Workshop Tools

Maintaining Your Workshop Tool Storage

Maintaining your workshop tool storage is crucial for ensuring the longevity of your tools and the efficiency of your workspace. Here are some essential tips to help you keep your tools and storage solutions in optimal condition:

1. Regular Cleaning and Dusting:

Regularly clean and dust your tools and storage areas to prevent the buildup of dirt, debris, or sawdust. Use a soft brush or cloth to remove any particles from your tools, toolboxes, shelves, or drawers. This not only keeps your tools clean and ready for use but also helps prevent the transfer of dirt or debris onto your projects.

2. Inspecting for Rust and Damage:

Periodically inspect your tools for signs of rust or damage. Rust can compromise the functionality and lifespan of your tools. If you notice any rust spots, use a wire brush or sandpaper to remove the rust and apply a rust-inhibiting solution. Check for any loose or damaged handles, blades, or parts and repair or replace them as necessary to ensure safe and efficient tool usage.

3. Replacing Worn Out or Broken Storage Solutions:

Over time, storage solutions such as toolboxes, shelves, or racks may become worn out or damaged. Replace any broken or malfunctioning storage solutions to maintain the integrity of your tool storage system. Invest in quality storage solutions that are sturdy and durable, as they will provide better protection and organization for your tools in the long run.

4. Embracing Minimalism and Avoiding Clutter:

Regularly declutter your workspace and remove any tools or equipment that are no longer needed or rarely used. Embrace a minimalist approach by keeping only essential tools within your workspace. This not only improves organization but also creates a more focused and efficient work environment. Consider donating or selling tools that are in good condition but no longer serve a purpose in your workshop.

By following these maintenance tips, you can ensure that your workshop tool storage remains in optimal condition, prolonging the lifespan of your tools and enhancing the efficiency of your workspace.

Related Article: When to Upgrade: 7 Signs Your Workshop Tools Need Replacement